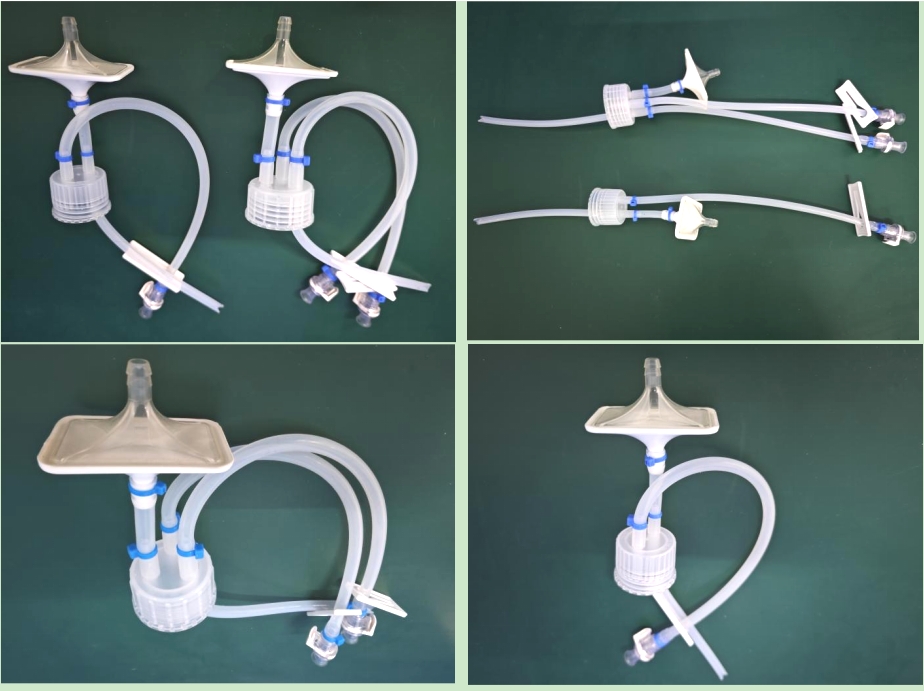

Steriled addition bottles kits can realize closed transfer and storage of liquids at the same time. Through tubing connection, they can effectively avoid the risk of external contamination, reduce customer tubing design, assembly, and sterilization time, and improve production efficiency.

The bottle cap system is made of one-piece injection molding using a custom mold, which has excellent sealing and stability and can withstand high temperature, high pressure or radiation sterilization. The bottle cap is made of high-quality polypropylene (PP) and has an integrated structure with the joint. It can be used with feeding bottles of different volumes. It is suitable for application scenarios such as feeding, harvesting, and sampling of bioreactors, as well as vacuum liquid suction or Buffer bottles, safety bottles, liquid collection bottles and mobile phase injection of filtration systems.

The material of the bottle kits meets the requirements of industrial biopharmaceutical companies. It can be customized to connect a variety of piping made of different materials according to needs to meet GMP production requirements.

Submit your requirements